jawcrusherjawcrusherjawcrusher

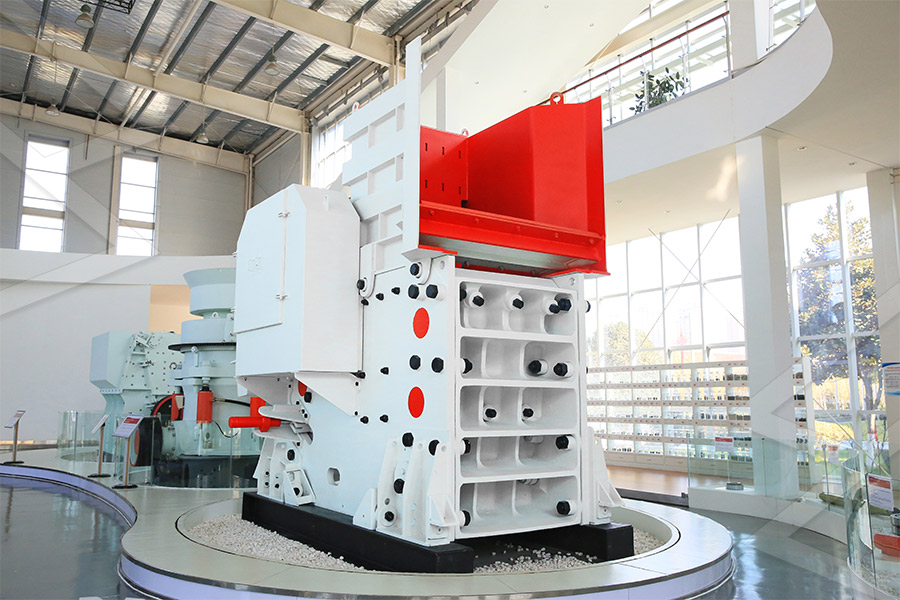

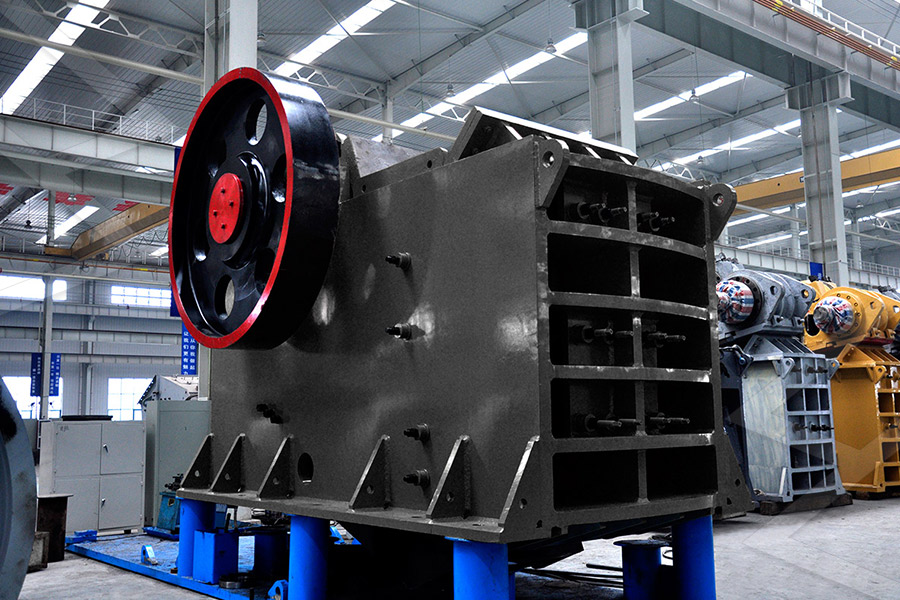

Jaw Crusher Crushing Plant Hard Rock Mining

2024年8月28日 — DOVE 60 TPH Jaw Crusher, DOVE Factory DOVE Jaw Crushers are supplied in large range of two models for Laboratory (0550 – 30 TPH), and sixteen models (45 – 1,000 TPH), for major rock crushing Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when Jaw Crusher Explained saVRee3 天之前 — JXSC has a wide selection of jaw crushers suitable for all kinds of ores and large materials, Jaw crusher is widely used in the first step for varieties of ore rock broken processJaw Crusher Mineral Crushing Aggregate 2024年2月5日 — A jaw crusher is a robust, essential and rugged crusher used primarily in mining and construction for the initial crushing of large rocks and ore Positioned at the start of the crushing process, it uses How Does a Jaw Crusher Work? A Simple Guide

What Is A Jaw Crusher MEKA

All jaw crushers feature two jaws: one of which is fixed while the other moves The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity A larger feed opening increases material intake and ensures that the rocks enter the jaw ® C Series™ jaw crushers 1 天前 — The RockSizer upthrust single toggle design has specific features that benefit the user with lower manganese wear rates and power consumption per tonne of material crushed with improved product shape Jaw Crushers Parker Plant2024年8月22日 — CRJ3042 The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machineCedarapids JW42 Jaw Crusher MPS

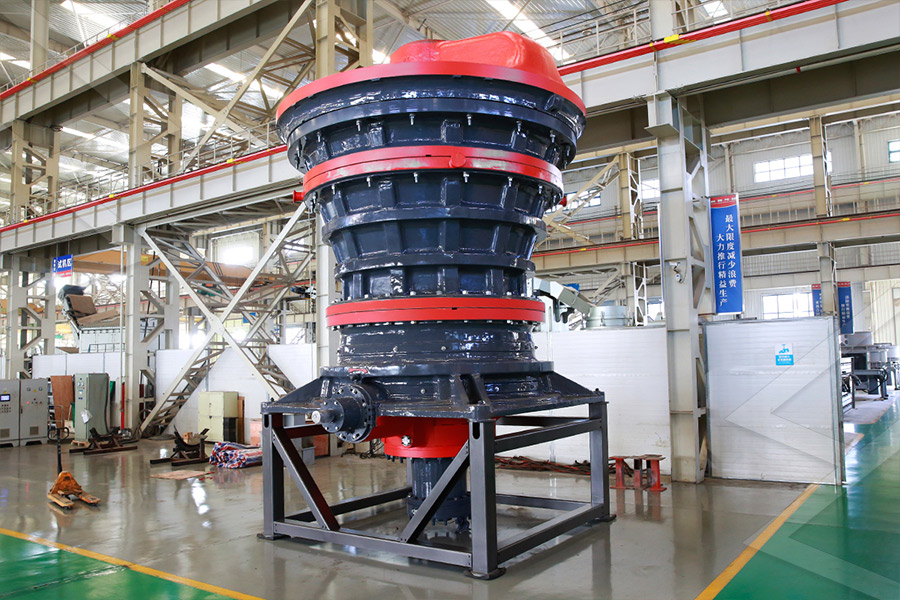

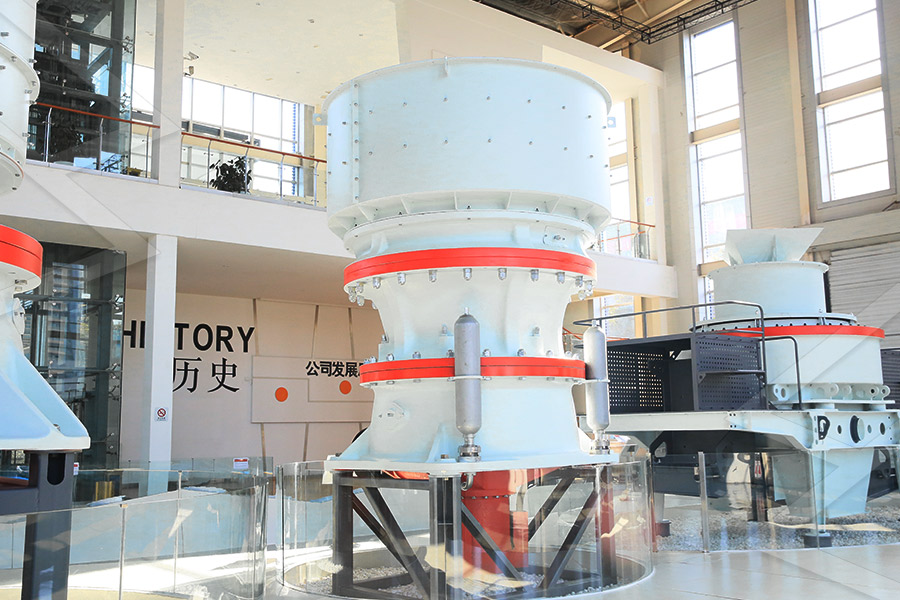

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年5月27日 — FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export BaseBased on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customers1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic Cylinder 8 Toggle Plate 9 Swing JawWhat Is A Jaw Crusher MEKA2023年2月21日 — A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a Vshaped configuration As the movable jaw plate moves back and forth, it crushes the material against the fixed jaw plateThe Ultimate Guide to Jaw Crushing Machines: Types2024年8月21日 — jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a Jaw Crushers

Jaw Crusher SpringerLink

2023年6月21日 — The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw 2024年8月22日 — The Premiertrak 400X Jaw Crusher is designed for medium scale operators in quarrying, demolition, recycling, and mining applicationsJaw Crusher Premiertrak 400X R400X 2024年2月5日 — Crushing Stage Objective Equipment Used Initial Feed Size Size Reduction Process Details; Primary Crushing: To reduce large and bulky materials to a manageable sizeHow Does a Jaw Crusher Work? A Simple Guide JXSC2020年4月1日 — SELECTION OF JAW PLATES Sandvik offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of quarrying and mining applicationsSANDVIK JAW CRUSHER SERIES Sandvik Mining and

A Guide to Types of Jaw Crushers for Crushing

2023年2月15日 — Jaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces There are several types of jaw A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery What Are Jaw Crushers and How Do They Work?2023年2月28日 — Learn everything you need to know about primary jaw crushers in this comprehensive guide Discover how they work, their applications, and where to buy them from reputable sources Whether you're in the mining or construction industry, this guide will help you make an informed decision when it comes to selecting the right primary jaw The Ultimate Guide to Primary Jaw Crushers: What They Are Sandvik QJ241 mobile jaw crusher is the most compact machine in the series and is ideal for smaller operations Like the rest of the range, it delivers maximum productivity with low operating costs, and has been designed with the user in mindQJ241 Mobile Jaw Crusher Compact Jaw Crusher SRP

McLanahan Jaw Crushers

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a doubletoggle Jaw Crusher Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers大量翻译例句关于"jaw crusher" – 英中词典以及8百万条中文译文例句。 梯形磨粉机主要由主机,减速机,浓缩粉,引风机,除尘器,管道装置,集成商和电机组成,磨等全系 列 包括 颚式 破碎机, 斗 式 提升 机,磨减速机,Vibraing给料机,主要框架,鼓风机,粉选矿厂,粉收集系统,管道设备和 jaw crusher 英中 – Linguee词典Jaw Crushers for precrushing of very hard, hard, mediumhard, brittle, tough, temperaturesensitive materials, grinding parts available in many steel typesJaw Crushers – fritschCrushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jawcrusher Construction Jaw crushers are heavyduty machines and hence must be robustly constructed The main frame is often made from cast iron or steel, connected with tiebolts It is commonly made in sections so that it can be Jaw Crusher an overview ScienceDirect Topics

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

2017年6月30日 — A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine 1 天前 — Hopper and Loading Belt Jaw Chamber Dust Suppression Water Spray Nozzle Extraction Belt with Dust Suppression Water Spray Nozzles Extraction Belt Drive Roller Loading Belt Speed Control Knob Left Side KJC503 Mobile Mini Jaw Crusher Komplet Striker mobile jaw crushers are available in a range of sizes and are fitted with world renowned jaw crushers The single toggle crushing action and design of jaw stock geometry perfected over many years gives Mobile Jaw Crushers Striker Celebrating 25 Find here Jaw Plates, Crusher Jaw Plate manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Jaw Plates, Crusher Jaw Plate across IndiaJaw Plates Crusher Jaw Plate Latest Price,

Jaw Crusher Parts Aftermarket Wear and Spare Parts GTEK

2 天之前 — Jaw crushers are mainly used as primary crushers in mining, construction materials, infrastructure, and other sectors As the start of a highproductivity crushing line, using highquality replacement parts is crucial to 2021年7月16日 — ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations® C Series™ jaw crushers Proven reliability and 2024年8月22日 — The Finlay® J1170 Stone Crusher is a compact and aggressive tracked jaw crusher The heartbeat of the machine is a robust hydrostatically driven jaw chamber which provides high capacity with large reduction ratiosJ1170 Stone Crusher Mobile Jaw Crusher Finlay2023年6月23日 — Jaw Crushers are not a shaping crusher Because they typically produce an elongated, flat and slabby product, Jaw Crushers are usually followed by a secondary crusher , such as a cone, impactor or roll crusher, for refining and further size reduction These crushers come in a range of styles and sizes and are capable of handling low How To Size A Jaw Crusher McLanahan

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, 2021年1月30日 — Abstract The vibrations of a vibrating jaw crusher model, excited by two selfsynchronizing unbalancedmass vibration exciters, with allowance for the interaction with the processed medium are examined It is found that the frequency range of stable antiphase synchronization of the exciter rotation required for normal operation of the SelfSynchronization of a Vibrating Jaw Crusher withIntroducing the Roco RYDER 1000: A DieselElectric Jaw Crusher Redefining Efficiency The Roco RYDER 1000 is a highperformance dieselelectric jaw crusherRYDER 1000 Jaw Crusher roco92023年9月7日 — Jaw Crushers are often used as primary crushers where the main duty is to produce a material that can be transported by belt conveyor to the subsequent stages of the plant They crush material via McLanahan Best Practices for Feeding Jaw

Jaw Crushers – MEKA

For material weighing 16 t/m³ or 100 lbs/ft³ Capacity values are indicative only, crusher performance may vary depending on the feed gradation, feed moisture content,crushability of the material, crusher rpm, installed Solution: Timely carry out lubrication and maintenance according to the maintenance manual, use the specified lubricating grease, and fill the grease in time according to the specified process;; Reasonably set the feeding height according to the feeding form to avoid the impact of material supply on the moving jaw 2 The Bearing Temperature is Too High20+ Common Faults of Jaw Crusher with Solutions MC2022年11月21日 — Our solutions for the hardest jobs Fields of application and design characteristics They are used in mines and quarries as primary crushers to crush blasted rockpile,Industrial Solutions Jaw crushers ThyssenKrupp2021年2月1日 — Learn about the features and benefits of the JW Series jaw crushers from , a leading manufacturer of crushing equipmentJaw Crushers JW Series

Jaw Crusher vs Cone Crusher: A Comparison

Crushing equipment has the seemingly simple job of breaking up massive boulders and rocks into smaller aggregate Something so straightforward is quite complex in practicality2023年9月6日 — For more than 20 years, Fodamon® Machinery has been providing efficient and effective stone crushing equipment and beneficiation solutions through the use of jaw crushers, hammer crushers, rotary dryers and other specialized toolsJaw Crusher, Stone Crusher, Ball Mill, Beneficiation 2024年8月20日 — The jaw crusher is one of the most commonly used crushing equipment in industrial processes worldwide As the primary crusher in many quarrying and mining operations, it effectively breaks down oversized feed material into smaller output sizesJaw Crusher Basics in 3 Minutes Industrial Technology stone crusher,stone mill,jaw crusher,impact crusher,cone crusher,mobile crusher,and all kinds of Mining Equipments are producted by Liming Road Bridge Heavy Industry, which is one of the biggest manufactories of stone crusher and mill machineStone Crusher,Stone Mill,Cone Crusher,Jaw Crusher,Impact

® C Series™ jaw crushers

® C Series™ jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity A larger feed opening increases material intake and ensures that the rocks enter the jaw 1 天前 — The RockSizer upthrust single toggle design has specific features that benefit the user with lower manganese wear rates and power consumption per tonne of material crushed with improved product shape Jaw Crushers Parker Plant2024年8月22日 — CRJ3042 The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machineCedarapids JW42 Jaw Crusher MPS2023年5月27日 — FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export BaseBased on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customersJaw Crusher VS Cone Crusher (A Comparison From 7 Points)

What Is A Jaw Crusher MEKA

1 Feed Chute 2 Drive Flywheel 3 Vbelts 4 Electric motor 5 Motor Stand 6 Settings and Damping Group 7 Hydraulic Cylinder 8 Toggle Plate 9 Swing Jaw2023年2月21日 — A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a Vshaped configuration As the movable jaw plate moves back and forth, it crushes the material against the fixed jaw plateThe Ultimate Guide to Jaw Crushing Machines: Types2024年8月21日 — jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a Jaw Crushers 2023年6月21日 — The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw Jaw Crusher SpringerLink

Jaw Crusher Premiertrak 400X R400X

2024年8月22日 — The Premiertrak 400X Jaw Crusher is designed for medium scale operators in quarrying, demolition, recycling, and mining applications2024年2月5日 — Crushing Stage Objective Equipment Used Initial Feed Size Size Reduction Process Details; Primary Crushing: To reduce large and bulky materials to a manageable sizeHow Does a Jaw Crusher Work? A Simple Guide JXSC